Waffle slabs are ribbed reinforced concrete slabs. A waffle slab often referred to as a ribbed slab, is a structural component that is plain on top and has a grid pattern on the bottom. A waffle slab also called a two-way joist slab got ribs running perpendicular to each other in two directions on the underside. This slab resembles pockets of waffles because of its grid pattern. Hence they are named Waffle slab systems.

For spans longer than 40 feet (12 metres), waffle slabs are chosen because they are stronger than flat slabs, flat slabs with drop panels, two-way slabs, one-way slabs, and one-way joist slabs. These are more expensive than other slabs but in turn, are more rigid and stable. Waffle slabs are apt for both ceiling and floor slabs. Slabs are one of the important structural components of a building. They provide a flat surface and help in transferring load. This article is about what is waffle slabs, the Construction process, Advantages and Disadvantages.

What is a waffle slab – Details and construction

A waffle slab is a type of slab that is appropriate for industrial and commercial buildings. Waffle slabs are also referred to as two-way joist slabs or ribbed slabs. They have a flat top and grids on the underside. It has greater strength than flat slabs and hence is suited for longer spans. It enables both distributed and point vertical actions. The bottom layer of concrete reinforcement in waffle slabs is replaced by concrete ribs running in two orthogonal directions. Additionally, the rib depth should range from 135mm to 235mm. Because the overall depth of the floor increases as the depth of the ribs does. The structure’s lateral loading is impacted by this.

Waffle slab construction details

The waffle slabs need only 70% of concrete and 80% of steel from the concrete and steel used for the construction of the raft slab. The construction stages of the waffle slab include the following

- The first step is to create the forms

- Place the formwork components in place.

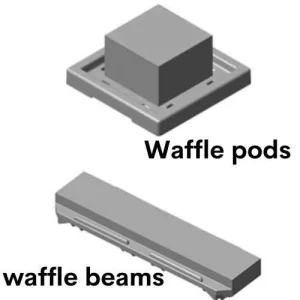

- Position your waffle pods or moulds on the shuttering. Generally, the pods are typically constructed of plastic, and they come in a variety of sizes and shapes. The size of the pod is determined by the requirements and span length. A significant number of pods are necessary for greater spans. Accordingly, the same size pods should be used for the entire slab.

- Place the support components horizontally and vertically according to the connectors.

- Lay out the waffle pods and spacer within the formwork in a grid pattern beginning at one corner, following the instructions in the design.

- Fix the pod corners to the framework using cube joints.

- Position reinforcement bars on the spacers between the waffle Pods.

- Reinforcement is added in the two directions after the formwork has been fixed.

- Lay the top mesh out according to the design specifications, then secure it where necessary.

- Making sure connecting ribs are filled, pour the concrete and give it a good vibrating.

- After the setting of the concrete, remove the frames into which the waffles are embedded. Then slowly remove the waffle forms.

The construction of a waffle slab can be done in three ways

- Insitu construction

- Precast construction

- Prefabricated construction

Insitu construction

This process entails placing formwork and pouring concrete over it. A slab is cast on-site in the desired size and according to the design.

Precast

Using this technique, the casting of the slab panel is done elsewhere, and it is then placed, connected, and reinforced with concrete.

Prefabricated

In this procedure, reinforcement is built into the slab panels using prefabricated steel bars. Slabs are manufactured elsewhere and brought to the location to be erected.

Advantages of Waffle slab

- It is suitable for large-span structures and can be achieved with less concrete and rebar than similar conventional slabs

- They require only a fewer number of columns.

- It possesses a higher load-carrying capacity

- It has higher structural stability

- They have a good aesthetic appearance.

- Waffle slabs are suitable for roof slabs and floor slabs.

- Waffle slabs have high vibration control capacity

- The construction of this slab can be done faster and easier.

- They are light weighted

- They require low construction costs, Hence they are economical when compared to other conventional slabs of the same span

- It requires only less amount concrete and can be reinforced with mesh or rebars.

Disadvantages of Waffle slab

- Requires Expensive formwork

- Requires skilled workmen and supervision for the construction of waffle slabs.

- Higher maintenance cost

- The increase in the depth of ribs leads to an increase in the floor height.

- This type of slab is not suitable for windy and slopy areas.

One comment

Comments are closed.