Cofferdams are enclosures built inside bodies of water such as lakes and rivers to provide a dry working environment throughout the construction period. Cofferdams are temporary dykes that are built across a body of water. They allow the water to be pumped outside, ensuring a clean and dry construction site.

This article is about the significance and definition of Cofferdam and about the different types of cofferdams preferred in construction works.

Significance of cofferdams

Construction in water is the most challenging task in civil engineering. A safe and dry working environment is necessary to preserve the project’s safety and construction quality. However, various strategies are used to construct structures in the water and maintain the area’s dryness. One of the most popular and widely utilised ways is the use of cofferdam.

Related posts from vincivilworld

What is a Cofferdam?

Making cofferdam involves building watertight barriers all around the construction site, pumping the water out to expose the water, and then erecting the cofferdams. For bridge piers, marine jetties, ports, etc. cofferdams are preferred. Size, water depth, water flow velocity, and other factors affect the design and types of cofferdam. Let us have a look into the types of cofferdams popularly used in construction.

Types of cofferdams

Depending on the design requirements, water depth, soil conditions, type of material used, etc., coffer dams are classified into many types.

- Earth cofferdam

- Rock fill cofferdam

- Single sheet pile cofferdam

- Double-wall sheet piling cofferdam

- Braced cofferdam

- Cellular cofferdam

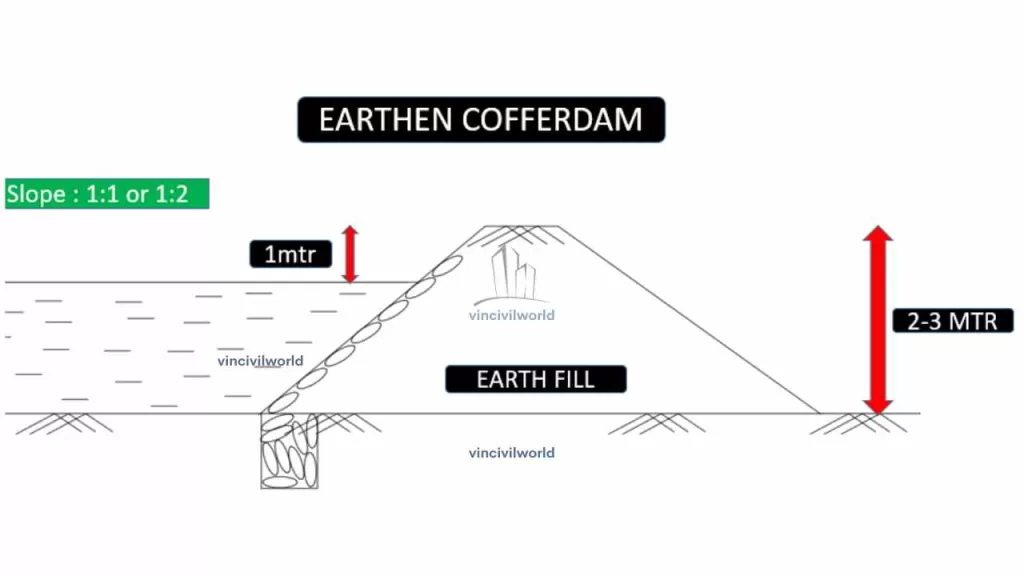

Earthen cofferdam

Earthen cofferdam is the most common and simplest type of cofferdam. They are appropriate for locations with minimal water depth and water current. Sand, soil, clay, and boulders that are readily available locally are used to construct earthen cofferdam. The earthen cofferdam must be at least one metre above the maximum water level.

When an area of excavation is quite extensive, earthen cofferdam is used and require a sizable base area. To withstand water pressure and seepage, impervious clay core or sheet piles are driven in the centre. In order to prevent scouring and possible dam failures, the upstream side is stone-pitched. These technologies do not, however, completely provide waterproof zones. Generally, to remove the water, pumps and waterproofing systems must be installed.

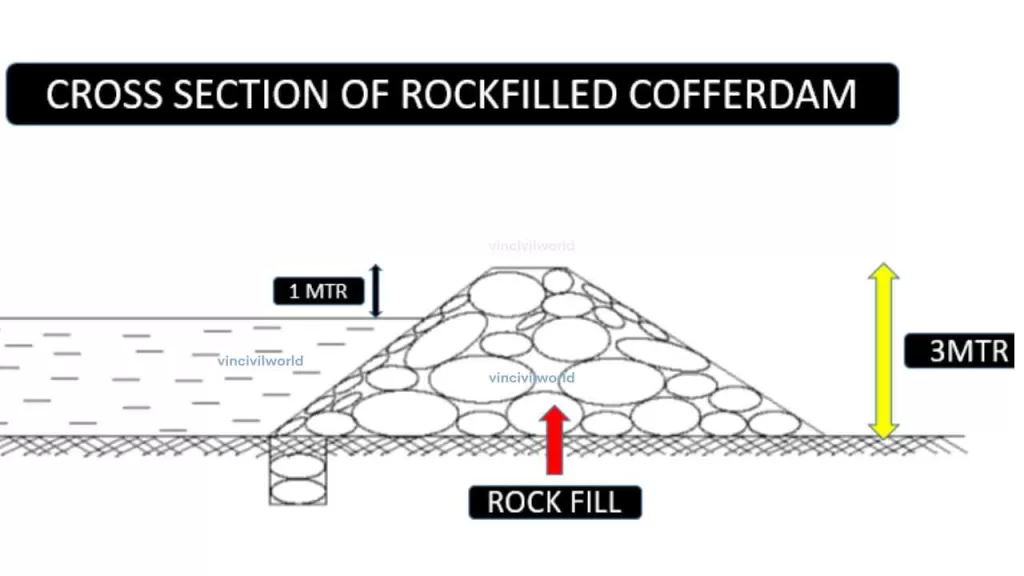

Rock-fill cofferdams

When compared to earthen cofferdams, rockfill cofferdams are superior. The choice of rockfill dams is influenced by the cost and availability of rocks in the area. Generally, the rockfill dam’s maximum height should be limited to under 10 feet. The rockfill area is pervious and will be lined with an impervious clay layer to prevent seepage and dam failure.

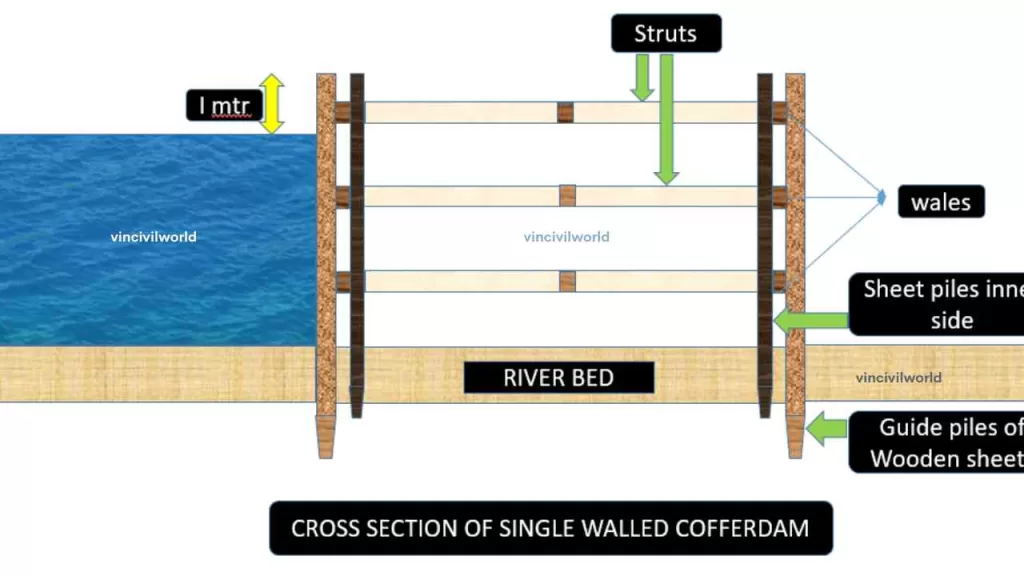

Single walled cofferdams

When the depth of the water is less than 6 metres and the area of work is localised, such as on a bridge pier, single-walled cofferdams are preferred. Basically, single-walled coffer dams are primarily built by driving steel sheets into the inside as a support layer after driving timber sheets into the exterior as guide piles. In situations where the water is deep, guide piles may be steel sections.

After the guide piles have been driven, wales or runners made of wood logs are bolted to the guide piles at appropriate vertical intervals. Wales are used to position the inside sheets’ distance from the wooden planks at a specific distance as shown in the figure. Mostly, these wales are fastened to the sheets using bolts from both sides.

The inside sheet piles have strong bracing. Sandbags are positioned on both sides of the walls to increase stability even more. For clay, the penetration depth should be approximately 1 metre, 0.5-0.75 metres for sand, and 0.25-0.5 metres for gravel, etc. Construction can begin when the interior water has been pumped out.

Also Read : Reservoirs vs Dams – Reservoir – types and functions

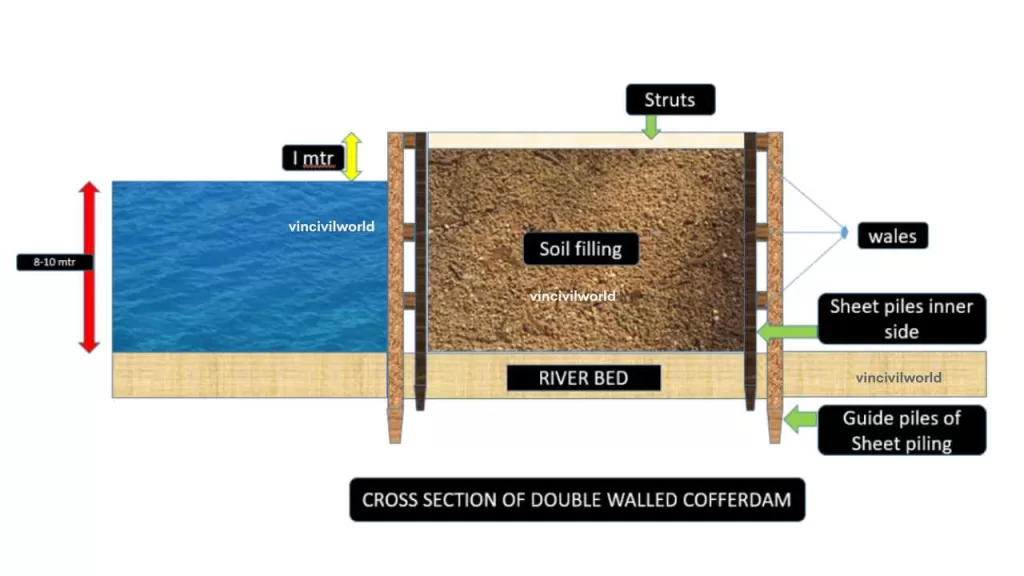

Double walled cofferdams

Double-walled cofferdams are preferred when the construction area is large, the water depth is higher than 6 metres, and single-walled cofferdams appear to be uneconomical. Double-walled cofferdams Consist of two straight, parallel vertical walls of sheet piling coupled together, with the space between them filled with soil. If the height is greater than 3 mtr, double wall sheet piles must be strutted as illustrated in the figure.

In order to give stability to the cofferdam, the filling materials must be carefully chosen while taking the coefficient of friction into account. The sheet piles are driven into the bed in the upstream area to a good depth to avoid leaking from the ground below.

One comment

Comments are closed.