Impact test on aggregate is determines the ability of an aggregate to withstand sudden loads. Aggregates are the significant factor that contributes adequate strength to concrete. Therefore it is important to obtain the right quality aggregate for construction. Aggregates are often subjected to impact due to the movement of vehicles on road. Hence it should possess good impact resistance or else it results in disintegration and breaking into pieces. The aggregate impact value gives the relative measure of aggregate resistance to sudden shocks or loads. So in this article, we explain the procedures of the aggregate impact test for determining the impact value.

Tests on aggregates

Different types of tests are done to determine their properties like

- Strength

- Toughness

- Hardness

- Shape

- Water Absorption etc.

Following are the tests conducted to ascertain the suitability of aggregates.

- Crushing test

- Abrasion test

- Impact test

- Soundness test

- Water absorption test

- Flakiness index test

- Elongation index test

- Bulk specific gravity test

- Polishing test

Must read : Los angeles abrasion test on aggregates

Must read : 9 Important test on bitumen for flexible pavements

Aggregate Impact Test

The aggregate impact test determines the ability of an aggregate to withstand sudden loads. During sudden loads, the aggregates may break into pieces. Hence to analyse to provide the adequate quality we perform this aggregate test.

Must Read : Aggregate crushing test to find strength of aggregate

Impact test Relevant codes:

- IS 2386(Part 4 ): 1963

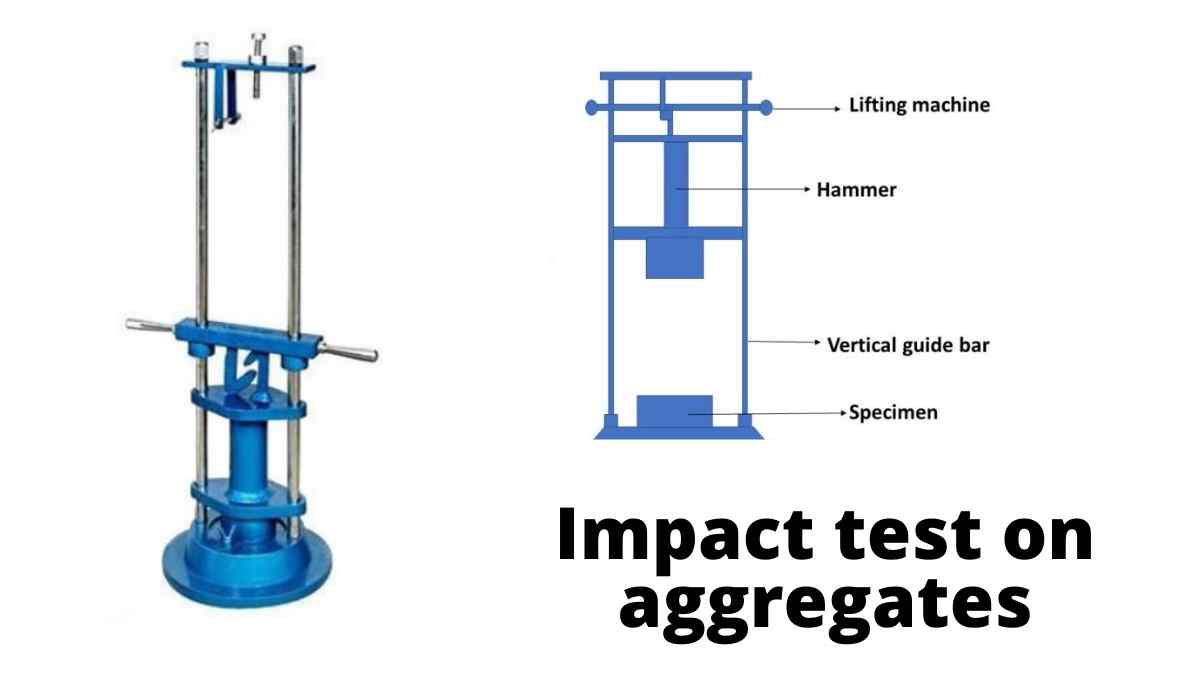

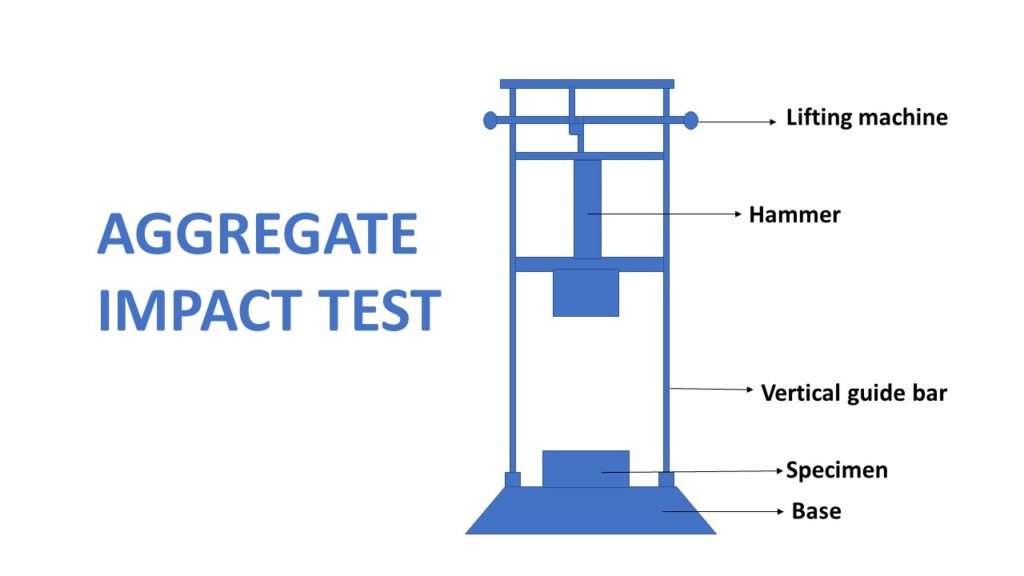

Apparatus required impact test

- Impact testing machine

- A cylindrical steel cup with 102mm diameter and 50mm depth

- Hammer with 132- 137 N weight

- Weighing machine

- Tapping rod

- Dry oven

- Sieve: 12.5mm, 10mm and 2.36 mm

Test Procedure of aggregate Impact test

- First, take some aggregate sample which retains in 10 mm IS sieve and passes through 12.5 mm IS sieve.

- Then oven-dry the specimen at 100 to 110 degree Celsius for four hours. Now weigh the dry samples and record them as W1.

- After that, take a measure and fill about one- third of the test sample and tamp with 25 strokes.

- Repeat these steps until we fill the measure. After filling remove the excess aggregate from the surface.

- Then place the sample in the firm steel cup at the base of the impact testing machine.

- Raise the hammer at a height of 380 mm and allow them to free fall 15 times at regular intervals on the specimen.

- Then remove the crushed aggregate from the cup and sieve them using a 2.36 IS sieve.

- Weight the aggregate which passes through the sieve to an accuracy of 0.1 g and Record it as W2.

- Also, weigh the aggregate which retains on the sieve and record it as W3.

- If the total weights W2 and W3 are less than W1 by more than one per cent, Then we reject the results and again repeat the test. Thus two tests should be made.

Formula for Abrasion Impact test value

The ratio of aggregate which passes through the sieve to the total weight of sample in each test in terms of percentage is the impact value of aggregate.

Now we compute the impact value using these two test using the formula below.

Aggregate impact value = W2/ W1 *100

where,

W2 – Weight of aggregate which passes through the IS sieve 2.36mm.

W1 – Weight of oven-dried aggregate.

For good quality aggregate, the impact value should not exceed 30% for concrete work and 45 % for base course.

| Aggregate Impact Value | Classification |

| <20% | Exceptionally Strong |

| 10 – 20% | Strong |

| 20-30% | Satisfactory for road surfacing |

| >35% | Weak for road surfacing |