Aluminium composite panel popularly known as an ACP sheet is a new-age panelling material used for building exteriors (facades), interiors, kitchen cabinets, and signage applications.

The aluminium composite panel are flat panels having a non-aluminium core sandwiched between two thin coil-coated aluminium sheets. Aluminum Composite Panel is the most durable and flexible decorative surface material available with enhanced performance properties. This article is about the manufacturing process, Types, Advantages, and applications of ACP sheets.

What are Aluminium Composite panels or ACP sheets?

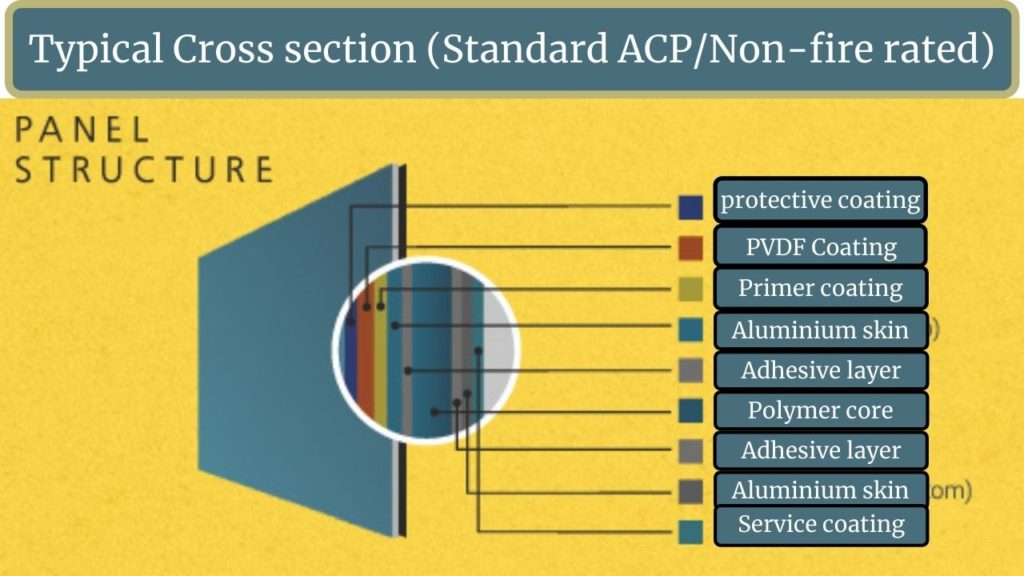

Aluminium composite panels are made up of two thin layers of aluminium sheets layered over a polymer core. Accordingly, the ACP sheet’s polymer core is made of Low-Density Polyethylene (LDPE) or Polyurethane. The ingredients that make up these polymer cores are flammable and not fire-resistant. Since aluminium has a low melting point, the Aluminium composite panel is more flammable due to the presence of the combustible polymer core. ACP sheets can’t be used in regions where there is a high risk of fire because of the combustible polymer core.

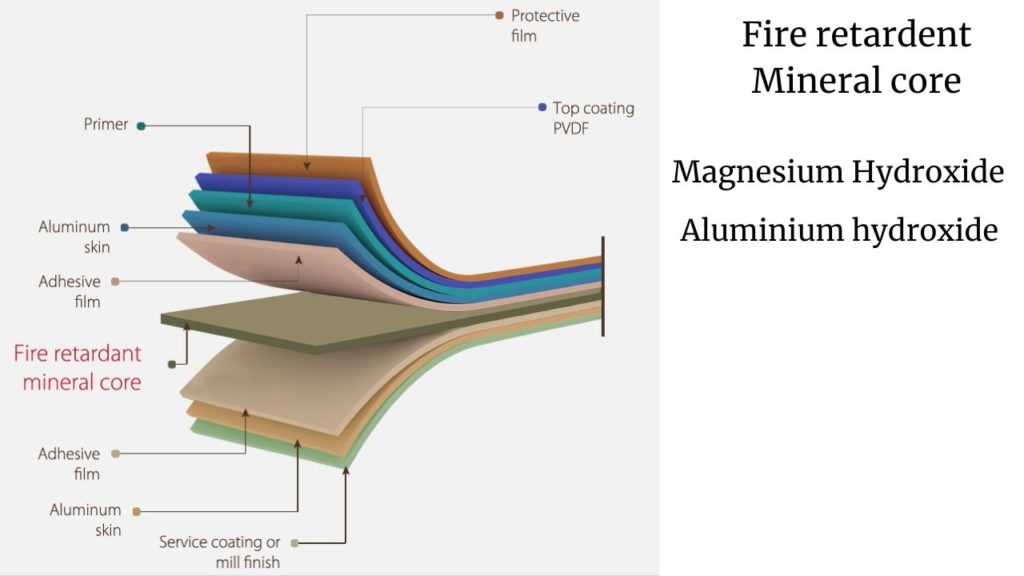

To improve fire resistance, polymer cores should be properly treated, or a non-combustible mineral fibre FR core sandwiched between two layers of aluminium skins should be used. Accordingly, to preserve the ACP sheets, polyvinylidene fluoride (PVDF), fluoropolymer resin (FEVE), polyester coating, and other materials are used. Generally, Aluminium composite panel sizes typically come in thicknesses of 2 mm, 3 mm, 4 mm, and 6 mm.

Types of Aluminium Composite Panel /ACP sheets

Depending on the usage and fire rating standards ACP sheets are classified into two categories

- Non-fire-rated grade

- Fire-rated grade /A2 grade

Non-fire-rated Aluminium Composite Panel sheets

Aluminum Composite panels constitute two thin layers of aluminium sheets with a sandwiched polymer core. Generally, the polymer core of the Aluminium Composite Panel uses Low-Density Polyethylene (LDPE) or Polyurethane. However, these sheets are combustible and may catch fire and are considered non-fire-rated ACP sheets. Therefore, the Usage of these sheets is to be restricted according to the fire rating. A typical cross-section of a non-fire-rated ACP sheet is shown below.

Fire-rated Aluminium Composite Panel

The fire-rated Aluminium Composite Panel can resist fire for up to 2 hours depending on the core material. The main difference between fire-rated ACP and Standard ACP sheets is in the core materials. The core of the Standard ACP uses LDPE/HDPE whereas the fire-rated ACP uses a specially formulated fire-resistant mineral core. Generally, magnesium hydroxide is used as a core for superior fire retarding properties. However, Fire Grade Aluminium Composite Panels as the name implies have the unique feature of withstanding high temperatures. Fire Retardant ACP (A2 GRADE) is the highest grade ACP with nearly 90% of inorganic mineral content.

Advantages of Aluminium Composite Panel

Aluminium Composite Panel is extensively used nowadays due to lot of unique properties. Let us feature some of the unique qualities which make it superior to any other panelling material.

Lightweight

The Aluminium Composite Panel is light in weight compared to steel and other construction materials. This drastically reduces the design loads on the structure with large spans and huge areas involved. ACP sheets are easy to lift and erect. Altogether, drastically reduces manpower and construction expenses and maintains the schedule.

Flexible

ACP sheet is flexible and very easy to work with. The fixing framework assembly is simple and installation is easy and fast.

Availability and colour choices

The wide scope of finishes that this composite panel permits give it extraordinary flexibility. From textured to solid, mirror, or wood type, the Aluminium composite board could match any architectural theme. Generally, the colour and texture of actual stone and wood are effectively made of aluminium.

Environmental friendly

An aluminium composite panel is an environmentally sustainable material and is made of 85% recycled aluminium content. Additionally, the core material and cover sheets of ACP can be reused constantly.

Dimensional stability

Altogether, Acp sheets got high dimensional stability and the material can remain stable for a long period without changing the dimensions.

Smooth and elegant

ACP surface is smooth and elegant and can create a pleasant and elegant look on the building exteriors.

Cost

ACP sheet is the most economical panelling option when compared with other panelling materials. The cost depends on the core materials. However, fire-grade materials are costlier than standard non-fire-rated ACP.

Weather resistant and Durable

ACP panels are UV-resistant and chemical resistant. Basically, they are unbreakable stain-resistant,weather-resistant, termite-resistant, moisture-resistant, and anti-fungal.

Applications of Aluminium composite panel

ACP sheet is mainly used for a wide range of applications due to its extraordinary qualities. Major uses of the ACP sheet are as follows.

- External and internal architectural cladding

- Internal partition

- False ceilings

- Signage

- Machine coverings

- Container construction

External and internal architectural cladding/partitions

ACP sheets are used for external cladding/facade works. Thanks to their versatile properties like UV resistance, fire-resistant, and durability. Generally, ACP sheets are available in plenty of colour choices to match any architectural theme. Particularly, the lightweight properties and easy fixing methods and speedy construction make the ACP sheet the preferred choice for facades/partitions.

Internal partitions

ACP sheets in combination with aluminium, UPVC etc are used for office cabins and internal partitions. Another key point is that partitions can be done with minimal space wastage.

Signage

ACP is used to render a wide variety of flexible exterior signs, as signage and hoardings are being used for exterior applications and must survive changes in temperature or weather

Interior work

ACP sheets are used for interior applications such as wall coverings, false ceilings, cupboards, portable kitchen cabinets, tabletops, column covers, and more.

Conclusion

Aluminium composite panels are Green and environmentally friendly, easy to clean, and can shorten the construction period. Above all, ACP panels are resistant to corrosion and prevent acid and alkali, and other types of corrosion. Due to these versatile properties, ACP sheets are one of the popular choices in the construction sector.

One comment

Comments are closed.